About my work

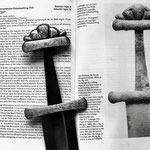

Even I work on original creations, the swords I present here are inspired from museum models.

It's possible to make reenactment of a museum sword from original measurements or make a sword from your own drawing and feeling.

Troughout the year, I work with many specialists people (archaeologists, collectors).

Aesthetic and especially proportions are really important points in the building of a sword.

Proportions allow a good balance, an optimum handling and a accurate behavior of a sword.

That is why I made the choice to make fully fonctional like the Ancestors did.

I practice my job by hand with traditional knifemaker tools in my workshop.

I make my swords from A to Z.

On some projects, I work with specialized craftmen.

Every parts of the swords I make are crafted with blacksmithing techniques, even when the crossguards and pommels (shapes and holes) are made of iron, copper or brass/bronze.

The fullers you can find on some blades are made with power hammer matrix.

Sometimes, some crossguard and pommels can be made in several parts.

I propose 3 ranges of swords:

-Swords forged with modern monosteel, that offers a good flexibility and hard edges (about 55 Hrc).

These swords are easy to maintain and you can use it for intensive work.

Finish are made by hand.

You can find a work in progress of this range here.

-Swords forged with laminated steel/multilayered steel are a good compromise between efficiency and historicity. These blades are forged with different hard steel of equal hardness. The cutting edges are a little bit harder than the homogeneous steel swords and it keep a good flexibility too (good spring effect).

The crossguards and pommels are forged with old wrought iron (about XIXth century).

Sometimes, this wrought iron recalls the aesthetic aspect of an iron made with blast furnace technique.

On demand, I can increase the revelation of the structure of this metal (damascus apsect, or not).

These blades are made with hard steels (about 56 Hrc).

Finish are made by hand.

You can find a work in progress of this range here.

-Swords made with iron and steel produced direcly from the iron ore with the bloomery iron furnace technic (craft method). This range is the most accomplished way that I can propose for historical reenactment.

Here, I work from raw iron/steel blooms made with metallurgists friends for the making of these homemade materials.

I make the refinement of this raw material myself.

I make my own brass/bronze for native copper and pure zinc or pure tin (from cassiterite ore and tin quartz made).

During the making of the sword, I take a big care of using only historic materials (in particular for the natural glue I make for the traditional mount.

I work with craft leather (calf, goat, salmon, trout, etc...).

I make my own dyeing from natural pigments.

The hardness of the blade can depend of period and on type of sword.

I can work with soft iron for the antique swords, and I can make hard blade with a good spring effect for the late models too.

Hardness on the cutting edges can be high with this technique. I advise against going beyond 58 Hrc. 58 Hrc seems to be the maximum hardeness known at the end of the Middle-Age period.

Finish are made by

hand.

You can find a work in progress of this range here.

Customization:

-For many years, customers ask me to put a relic into the pommel or into the handle for example.

It's possible to put cristal rock on the surface of a pommel with a little relic hidden behind (like a hair strand for example).

I can make a little cavity (about 6 mm diameter) into the pommel to put a relic too. This cavity is closed with a stopper (made of silver, bronze or iron).

Often, for the relic, I use natural sands from different places:

Sand from the Holy Sepulchre of Jerusalem or sand from the Western Wall of Jeruzalem too.

Sand from Le Mont Saint-Michel in France or sand from of real Pilgrimage of Compostela (camino de Santiago) made in 2004, some little rock that I took in the Sad Hill cemetary (Burgos) built for the film "The Good, The Bad, The Ugly", and many other materials that I took during many other expeditions.

-Making of the handle with bone, horn, wood, mammoth ivory, natural leather, natural silk velvet made in France,...

-It's possible to make engravings on the different part of the sword (blade, crossguard or pommel).

-Silver plating and gilding with pure gold 1000/1000 on ferrous and non-ferrous parts of the sword (blade, crossguard, pommel).

Hot gilding mercury amalgam.

-Enamelled pommel.

-Inlays/overlay made of brass, copper or silver wire. I use two techniques:

Traditional dovetail inlay technique or traditional scandinavian method inspired from the japanese actual technique.

A video shot by Nathanaël Dos Reis, PhD student in Medieval History, in January 2023

A video shot for the Medieval TV channel, autumn 2021